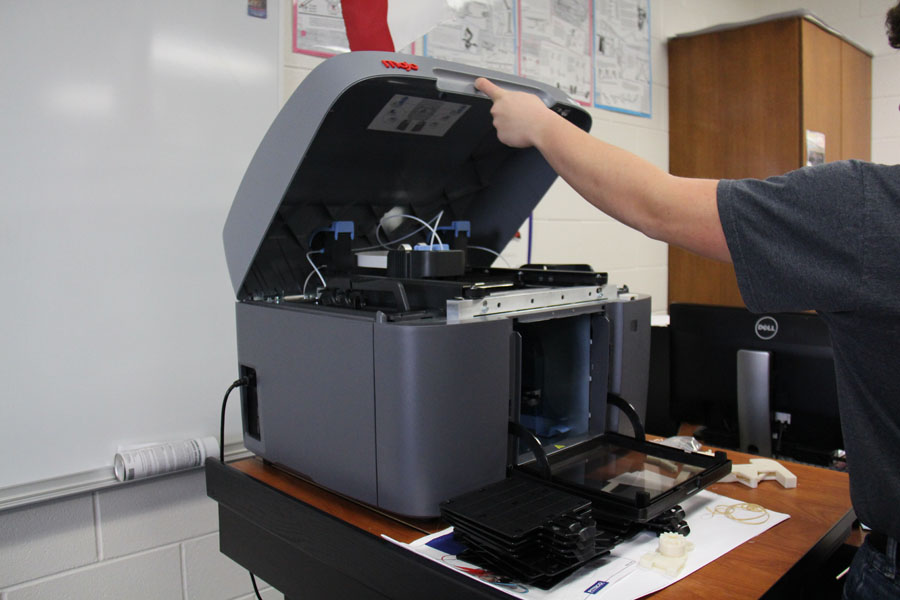

The LHS engineering department is working with cutting-edge 3-D pring technology in Brent Berryman’s engineering classes. 3D printers make parts and products using a computer-driven, additive process, one layer at a time. The school purchased their own 3D printer for $10,000 in 2012.

“3D printers are being used in almost every industry,” Brent Berryman, CTE coordinator and engineering teacher, said. “They are especially popular in the medical field reproducing prosthetics, etc.”

The printer can produce solid parts from 3D drawing software. LHS students have made i-phone cases, a trebuchet (type of catapult), rubber band launchers, sunglasses and more.

“If the students go into any type of engineering or design career they will need to understand the importance of this tool and how to operate it,” Berryman said. “The printer helps them understand the importance of precision and tolerances in the engineering and design process.”

The process of printing the items is very long and tedious. It, like engineering, requires patience and attention to detail.

Junior Nathan Terrien plans on being a computer engineer, which would involve making parts for computers.

“I’ve learned a lot about using 3D designing programs, specifically AutoCAD,” said Terrien. “Knowing how to use these programs will help me in my future career choice.”