The click of the mouse triggers the printer to power on with the slow hum of the fans. This is his fifth attempt to get the meticulous dimensions just right. He sits waiting, hoping that this is finally the successful attempt he has been waiting for.

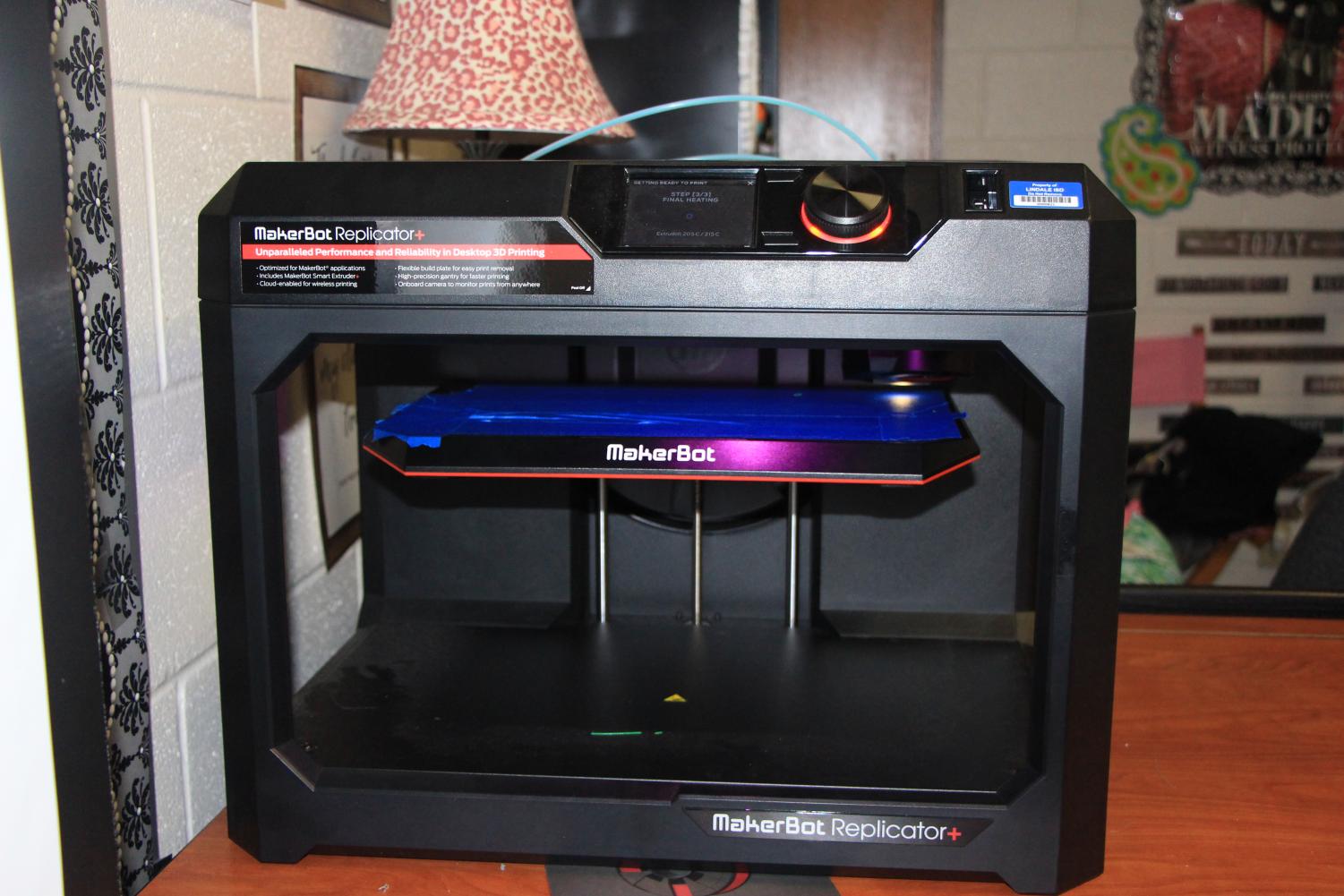

Sophomore engineering student Joshua Doyle used the engineering class’ 3D printer to print a hard drive bay to use in his computer at home. The engineering class got a new 3D printer last year that they use in many of their projects.

“[This project] was kinda open ended, he had been working on it over the summer and he asked if he could work on it in class,” Wheat said. “[So] I let him work on it before school and after school, and he printed it several times before it got as exact as it needed to be.”

Doyle had help from his brother, Ryan Doyle, during the summer to work on his 3D printer project, who taught him how to use AutoCAD, the software the 3D printer uses to print. Once school started Doyle came in the mornings before school and went after school almost every day, and he also had additional help from Wheat since this is his first year in the engineering class.

“[This project] was just for fun,” Doyle said. “I kinda more of a DIY kinda guy and if there is a chance to do it I’m going to do it. It was fun, it worked, and now I don’t have to buy one. I have the ability to say, hey I made this, and I have a little pride to it.”

This new 3D printer has been in the engineering class since last year. The class had one before but this is a newer version that is easier and more accurate for the students to use, giving more freedom and versatility to the teacher and the students of the engineering class.

“We can pretty well 3D print anything we design,” engineering teacher Tonya Wheat said. “We have had this 3d printer since last year, but we had one before that but this one is much simpler to use, and I think it’s more accurate.”

The 3D printer gives the engineering students the ability to have a physical version of what they’re trying to make in a relatively small amount of time. This gives the students the ability to make quick edits without much consequence.

“Right now [the students] are creating utensils,” Wheat said. “We’ll design those on AutoCAD, then we’ll [3D] print them, then go out to Mr.Morris’ class and make them out of metal so we actually have the utensils. Then we will go to Coach Phillips’ class and make wood handles for them, so we’re doing a lot of things [that are] cross-curricular.”

The students in the engineering class use the 3D printer almost every day, depending on the project they’re working on right now. Everything that is printed has to be made in the AutoCAD software in class and then approved by Wheat before it’s printed.

“[For our projects] we start with a small prototype that’s really small,” junior Stefan Gregg said. “Then we move on slowly scaling up and get bigger, like with the one we’re working on right now– we made it much thicker, then we added final touches.”

Currently, the engineering class is working on a new project that will use the 3D printer to allow the students to see what their final product will look like. The 3D printer gives the students the ability to have a physical version of it and edit how they see fit.

“I like [the engineering class because it gives me the ability to] to let my creativity and logic work together to make even the things that seem so simple,” Doyle said. “In the near future, I’m planning on moving to bigger and better [projects] with something in the works right now.